Introduction:

In modern electronic equipment, high-voltage isolation technology is the key to ensure system safety and reliability. Digital isolators and optocoupler chips, as the main components for realizing such high-voltage isolation, are widely used in the fields of power electronics, industrial automation, and medical equipment. High-voltage isolation test methods are an important means to assess how effectively these devices can prevent high-voltage current penetration and short-circuiting in practical applications. In this paper, we will discuss in detail the high-voltage isolation test methods for digital isolators and optocoupler chips, including test standards, test equipment, test process and considerations in practical applications.

Standards:

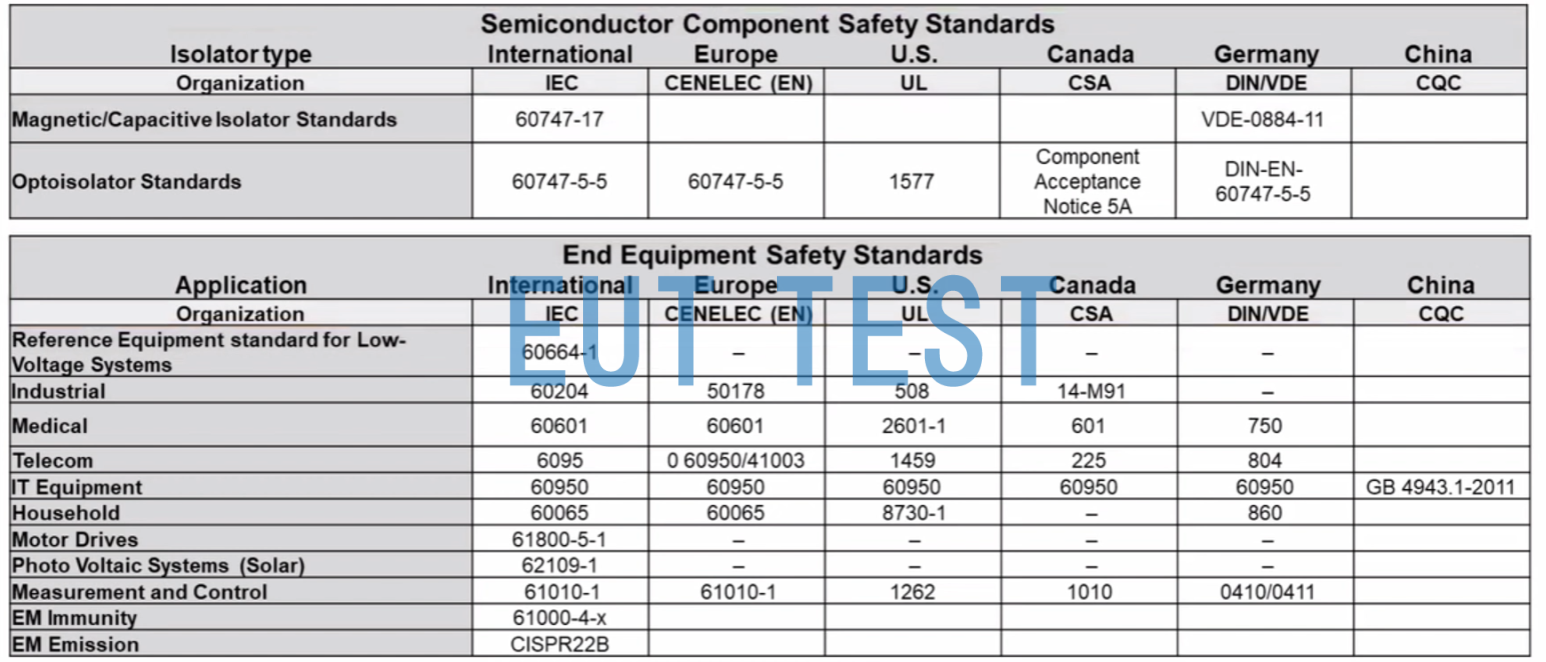

First of all, high-voltage isolation testing of digital isolators and optocoupler chips must follow the relevant international standards, such as IEC 60747-5-2, UL 1577,VDE 0884-11 etc. These standards specify the test parameters such as insulation withstand voltage, withstand voltage and insulation resistance of high-voltage isolation devices. When conducting high-voltage isolation tests, testers need to select the appropriate test standards for specific product characteristics to ensure the validity and reliability of the test results. For example, the IEC 60747-5-2 standard, which is particularly suitable for assessing the insulation performance of optocouplers and digital isolators, requires that a certain voltage be applied for a specified period of time to detect the insulation performance of the device under high voltage. The following table lists commonly used digital isolators and optocoupler chips for high voltage isolation testing andPartial Discharge Testof the relevant standard number:

Standard No. for High Voltage Isolation Test and Partial Discharge Test for Digital Isolators and Optocoupler Chips

As can be seen from the above chart, different industries and countries have different test standards for digital isolators or optocouplers. Chip makers should consider which country their products are exported to, and then choose the appropriate standard for testing.

Equipment for high voltage isolation testing:

After we learn the high-voltage isolation test standards, we need to select the test equipment according to the high-voltage isolation test standards, we have described in detail in the previous article on the test methods and examples of these devices-Digital Isolator - High Voltage Isolation Testing: Safety Standard Definitions and 7 Test Methods. Here is a list of just some of the common high voltage isolation test equipment included:

- High Voltage Power Supplies

- Insulation resistance tester

- Insulation Withstanding Voltage Tester

- Partial Discharge Tester

- Working Voltage Tester

- Surge Isolation Voltage Tester

- Hipot

etc.

High voltage power supplies are used to apply test voltages higher than the operating voltage to ensure the insulation performance of devices under extreme conditions. Insulation resistance testers are used to measure the insulation resistance value of a device to assess its long-term reliability. Voltage withstand testers are used to detect the leakage current of the device under high voltage conditions to ensure that it will not short-circuit or fail in a high-voltage environment. When selecting test equipment, testers should choose the appropriate test voltage and test time according to the rated voltage and insulation level of the device to be tested.

Flow of digital isolators and optocouplers for high voltage isolation testing:

During specific tests:

- It is first necessary to prepare the device to be tested and perform an initial inspection to ensure that there is no visible damage to the device's pins, board and package.

- Then, connect the test equipment and apply the specified test voltage while recording the leakage current and insulation resistance values of the equipment.

- Generally speaking, the test requires a gradual increase in voltage, starting from 0V and gradually rising to the specified test voltage, while observing the operating status of the device. If the leakage current is found to exceed the specified safety limit during the test, the test needs to be stopped immediately to prevent damage to the device.

- Once the test is completed, the data needs to be analyzed and organized.

Methods of analysis after high voltage isolation testing:

First, compare the test results with the requirements specified in the standard to determine whether the device meets the performance specifications for high-voltage isolation. If there are unqualified items, it is necessary to further analyze the causes, which may be due to factors such as manufacturing process, material selection or design defects. After determining the reasons for failure, corresponding improvement measures can be taken, such as optimizing the design, improving the material or adjusting the manufacturing process, in order to improve the high-voltage isolation performance of the device.

Insulation Classification:

In addition, we need to categorize the tested digital isolators and optocoupler chips according to the applied insulation level voltage according to the standard requirements and write it in the test report:

- Functional isolation: insulation required for operation, no need to consider protection against electric shock.

- Basic isolation: insulation with a single level of electrical protection. Risk of electric shock if single level fails

- SUPPLEMENTARY ISOLATION: Additional or supplementary protection used in conjunction with basic insulation to provide some protection in the event of failure of the basic insulation.

- Double isolation: insulation equivalent to a combination of basic and additional insulation

- Enhanced Isolation: Single insulation equivalent to double insulation or twice the basic insulation.

Summary:

In practical applications, the results of high-voltage isolation tests not only affect the performance of the device, but also relate to the overall reliability of the system. Therefore, in the design and selection, engineers need to give full consideration to the need for high-voltage isolation, select the appropriate digital isolator or optocoupler chip, and conduct high-voltage isolation tests in the early stages of product development, in order to identify and solve potential problems in a timely manner. At the same time, with the development of technology, many new digital isolators and optocoupler chips continue to emerge, they also show better performance in high-voltage isolation characteristics. Therefore, continuous attention to industry trends and technological advances is essential to improve the effectiveness and accuracy of high-voltage isolation testing.

To summarize, the high-voltage isolation test of digital isolator and optocoupler chips is a complex and important task, involving international standards, test equipment, test process and data analysis and other aspects. By reasonably selecting test standards and equipment and strictly following the test process, the high-voltage isolation performance of the device can be effectively evaluated to ensure its safety and reliability in practical applications. At the same time, with the continuous development of new technologies, test methods and equipment are also constantly updated, engineers need to keep abreast of the times, continuous learning, and improve the professional level of high-voltage isolation testing, in order to meet the ever-changing market demand and technical challenges.