Introduction:

This article mainly shows the EU CE certification of lamps and lanterns products EMC test requirements and common problems, including the EU certification standards for lamps and lanterns products, test items, limit value requirements and other content, and detailed introduction of lamps and lanterns and other similar products harmonic current test requirements and some did not pass the certification of the rectification case.

European Union CE marking on the lamps and lanterns products EMC test requirements - products applicable EMC standards.

- EN55015: Limits and methods of measurement for radio-nuisance characteristics of electrical lighting and similar equipment

- EN61547: Electromagnetic compatibility immunity requirements for equipment used for general illumination

- EN61000-3-2: Electromagnetic compatibility Limits Limits for harmonic current emissions (equipment input current ≤ 16A per phase)

- EN61000-3-3: Limitations on electromagnetic compatibility Limitations on voltage variations, voltage fluctuations and flicker in the public low-voltage supply system for equipment with a rated current of ≤16 A per phase and unconditional access.

- CISPR15-2018: CDNE test methods

- Lamp Testing Standards Check - December 2018

- IEC61000-3-2 2018 Electromagnetic compatibility emc - Harmonic current emission limits - Standard update

EMC Test Items for Lamps and Lighting Products

EMI (interference) testing.

- Conducted Interference Test

- Magnetic field radiation interference test (9kHz-30MHz)

- Electromagnetic radiation interference test (30MHz-300MHz)

- Harmonic Current Test

- Voltage fluctuation and flicker test

EMS (anti-interference) test.

- Electrostatic Discharge (ESD) immunity test

- Radiated Electromagnetic Field Immunity Test

- Electrical Fast Transient/Bulk Pulse (EFT/B) immunity test

- Surge (lightning strike) immunity test

- Injection current immunity test

- Industrial frequency magnetic field immunity test

- (Only for products containing Hall components, sensitive to magnetic field radiation should do this test)

- Voltage dips, short interruptions and voltage variations immunity test

Lamps and lanterns EMC common unqualified items and typical cases

LED bulbs/energy saving lamps (less than 25W): Harmonic and conduction test failures and rectification cases

European Union CE marking on the lamps and lanterns products EMC test requirements - harmonic current test requirements:

What is harmonic current?

In a low voltage power supply network, electrical and electronic equipment is supplied with a sinusoidal voltage, but the current is rectified by a diode, etc., and may be distorted. The supply system is 50 Hz alternating current, the second harmonic is 100 Hz, the third harmonic is 150 Hz, and so on.

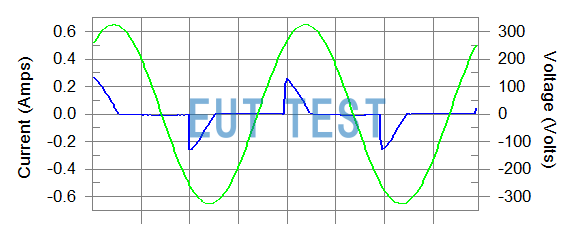

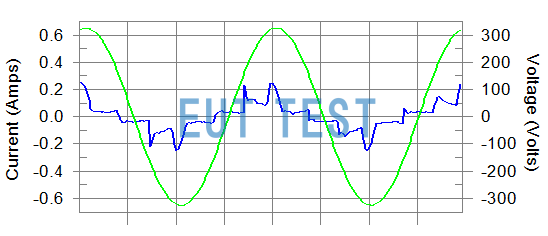

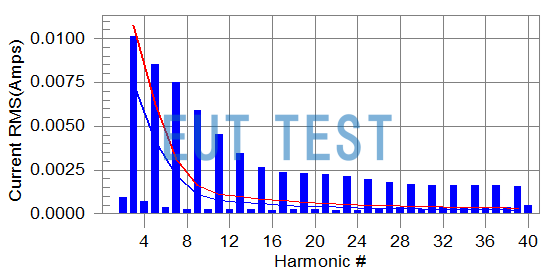

The following two graphs show the harmonic current test data displayed by the DPA500N Harmonic Flicker Test Analyzer provided by EUTTEST:

Harmonic current test data displayed by DPA500N Harmonic Flicker Test Analyzer-1

Harmonic current test data displayed by DPA500N Harmonic Flicker Test Analyzer-2

Harmonics Hazards

In the case of lighting equipment such as electronic ballasts, the hazards are not always apparent when used individually. But if tens of thousands of households intensive use, the harmonic current generated will cause serious pollution of the power system. Current harmonic content is too high electronic ballasts in the power grid in a road intensive use, will make the three-phase four-wire power supply system of the center line current increases dramatically, caused by the center line overload, it is easy to lead to electronic ballasts in batches of damage.

Excessive current harmonics cause additional power losses in the generator and heat generation. Harmonic currents increase the losses in the transformer and the grid.

Interference with or false operation of relay protection, automatic control devices and computers.

Impact on the accuracy of power measurements

Test standards for harmonic currents in lighting equipment:

- International Standard: IEC 61000-3-2

- European Standard:EN 61000-3-2

- National standard: GB 17625.1

Limit requirements for harmonic currents in lighting equipment:

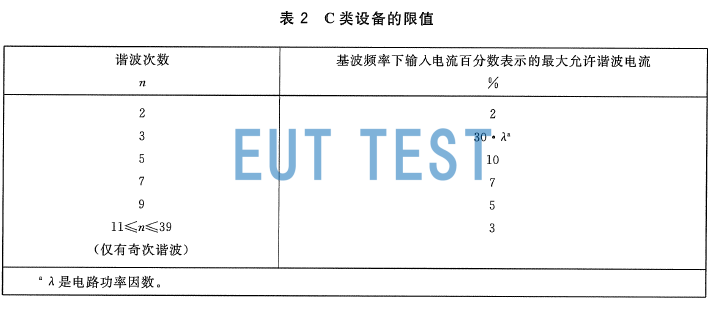

Active input power greater than 25 For lighting appliances with an active input power greater than 25 W, the harmonic currents shall not exceed the limits given in Table 2 for Class C equipment.

Lighting equipment is classified as Class C equipment and the limits for Class C equipment are.

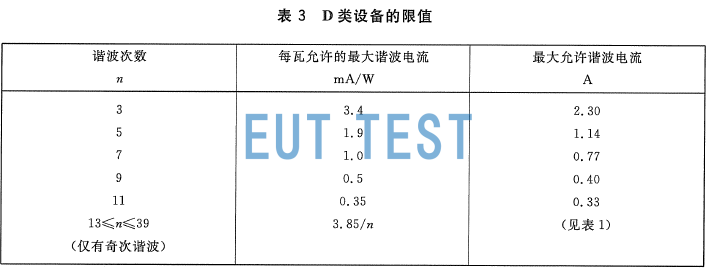

For discharge lamps with an active power of not more than 25 W, one of the following two requirements shall be met: the harmonic currents shall not exceed the limits for power-related Class D equipment in column 2 of Table 3, or: the 3rd harmonic current expressed as a percentage of the fundamental current shall not exceed 861 TP3 T and the 5th harmonic shall not exceed 611 TP3 T; and, assuming that the fundamental supply voltage crossings are 0°, the input current waveform shall begin to flow before 60°, with a final peak at or before 65° (if there are several peaks in a half-cycle), and shall be 90° before 90°, assuming that the fundamental supply voltage crosses zero. is 0°, the input current waveform should start circulating before 60°, have the last peak at or before 65° (if there are several peaks within half a cycle), and should not stop circulating before 90°.

Limit values for category D equipment

Note: Since LED lamps do not belong to the discharge lamp, according to the harmonic current standard: not belong to the B, C, D equipment products are categorized into class A. So many laboratories put the power less than LED lamps and LED drivers into class A products to test harmonics, class A limits are relatively loose. So many laboratories are less than the power of the LED lamps and LED drivers are classified as Class A products to test harmonics, Class A limits are relatively loose.

The case of EMC rectification of lighting products exported to the EU:

Electronic ballast radiation failure

Normal operation of the electronic ballast will produce radiation emitted outward, the receiving antenna will receive all the interference signals in the field during the test in the dark room of the radio wave, especially now!CISPR15-2018Radiation above 300MHz are specified in different RE radiation harassment test methods, to the most common airwave darkroom test method, after the completion of the RE test, if the test data exceeds the limit line must be rectified before the product can be marketed and sold.

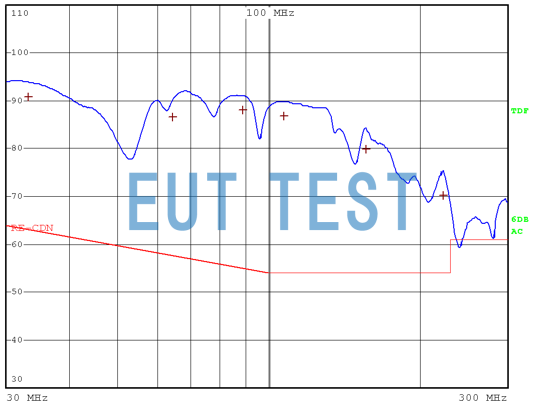

Test data for electronic ballasts exceeding the CISPR15 RE limit line

In order to solve the above problems, we recommend the use of EUTTEST's agent sales of theEMC rectification of radiated emissions by near-field probesProcess.

Rectification points.

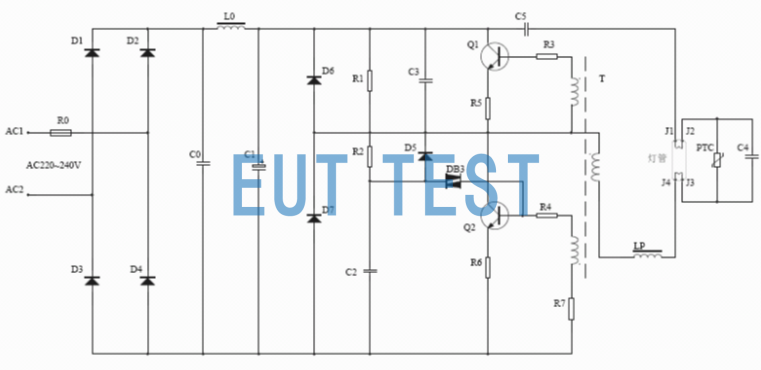

- Connect a bead in series in front of or behind the boost diode D6

- Connect a 102 capacitor in parallel with CMOS Q1.

- Connect an appropriate color ring inductor or bead in series with the power input line ground

Spectrum of radiation test of lamps exported to EU after rectification is completed

LED driver conduction and radiation rectification

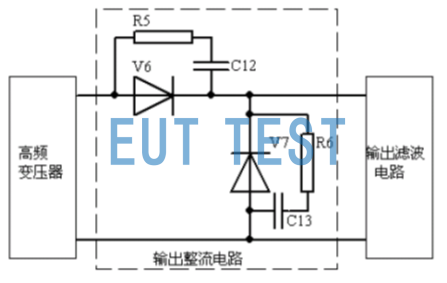

- The reverse recovery of the diode causes noise interference. As LED drivers often use industrial frequency rectifier diodes, high frequency rectifier diodes, renewable diodes, etc., these diodes are working in the switching state, in the diode from the blocking state to the conduction process, a very high voltage spike will be generated.

- Electromagnetic interference from switching action of switching tubes

- High-frequency transformer design, try to use electromagnetic shielding better core material, in the original, secondary side of the winding between the increase of a shielding layer, shielding layer good grounding.

- In the high-frequency transformer primary and secondary parallel connection of a Y1 capacitor, generally 2.2nF, capacitance maximum can not exceed 4.7 nF, otherwise it will cause the product leakage current is too large.

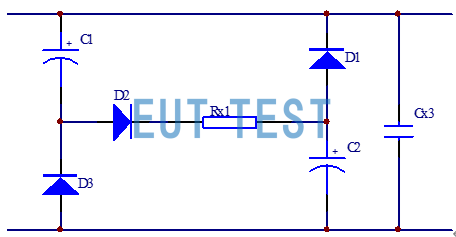

LED driver conduction and radiation rectification schematic

Power terminal nuisance voltage (conducted interference)

- Below 1MHz, differential mode interference is the most important source of interference, generally need to add a differential mode capacitor and/or differential mode inductor in the power input part, pay attention to the differential mode and common mode filter used in combination.

- Attention to the selection of filtering components, the same inductance of the common mode inductance, different core materials, the effect is very different, sometimes not the method is not right, is the quality of electronic components.

- Pay attention to the wiring of the circuit board, the main circuit input line and output line as far as possible to separate the line, for both ends of the wiring bracket lights, cable not attached to the metal shell, high-frequency transformers and heat sinks line, an effective way to deal with is to reduce the operating frequency of electronic ballasts, the power line into a twisted pair of wires also have a certain effect, and pay attention to the thickness of the line of the conductive interference suppression of the impact of the line.

Harmonic current testing and rectification process for energy saving lamps less than 25W:

The picture shows the circuit diagram of an energy-saving lamp

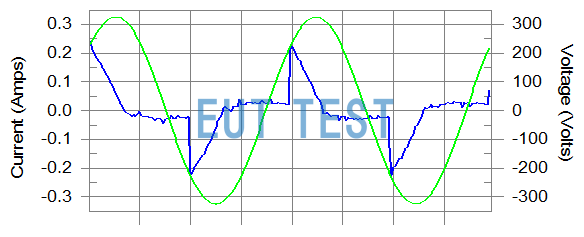

Harmonic current waveform distortion seen on DPA500N from EUTTEST

The Harmonic Test Analyzer DPA500N test software from EUTTEST shows harmonic currents exceeding the limit values.

Cause Analysis.

The product has a 10uF electrolytic capacitor after rectification, which leads to the third harmonic, the fifth harmonic exceeds the standard, or the current phase angle does not meet the requirements.

The product has a 10uF electrolytic capacitor after rectification with excessive harmonics in the channel.

Methods of rectification.

- Changing the electrolytic capacitor from 10uF to 2.7uF or 2.2uF greatly improved the situation.

- If there is a common mode inductor on the input side of the power supply, adjusting the inductance of the common mode inductor will also affect the harmonic current and phase angle of the energy-saving lamps.

- Adoption of a current-control circuit if the product size allows it.

- Introduce high-frequency feedback loop, adjust the parameters of the trigger capacitor, change the current on waveforms

- High-quality, high-power energy-saving lamps/electronic ballasts can adopt active power factor correction circuit (APFC)