EMC (Electromagnetic Compatibility) testing exists to ensure that your electronic or electrical equipment does not emit large amounts of electromagnetic interference (known as radiated and conducted emissions), or that there are several electromagnetic phenomena present in your equipment in succession as a result of normal functioning. Regulatory agencies around the world place limits on the level of emissions that can be produced by electronic and electrical products.

In addition, electromagnetic immunity testing is specified for a number of areas and product types. So we need to take a closer look at the applicability of radiated emission and radiated immunity testing to your product and determine exactly which standards apply.

What is the average EMC test pass rate?

There are very few statistics on this issue, as EMC test labs and governments do not need to collate the information. However, one of the largest studies, conducted by one lab, tallied a first time EMC test pass rate of only 50%! Failed tests can easily extend time to market by days to months, so it is important to be properly prepared for EMC testing.

68 Laboratory's statistical first EMC test pass rate is only 50%

5 Reasons to Care About EMC Testing - Do I Need to Care About EMC Testing?

While there are some exemptions for certain products, if you design, manufacture or import products with electronics inside, then you almost certainly need to be concerned about EMC.

1. Protection of the electromagnetic spectrum

We only have a limited amount of the electromagnetic spectrum, something that can be used for radio transmissions, microwave communications, x-ray machines and tons of other products.

Unfortunately, even electronic devices without transmitters emit electromagnetic radiation as a by-product of the switching currents and voltages inherent in electronic circuits. If the amount of unintended electromagnetic radiation generated by electronics is not limited, the electromagnetic spectrum may be adversely affected and the frequency bands reserved for radio transmissions may be interfered with.

Electronic devices without transmitters also emit electromagnetic radiation

As the number of non-wireless and wireless electronics continues to explode, the already allocated electromagnetic spectrum will become even more crowded. Protecting this essential resource is critical to ensure that equipment will continue to function properly in the future.

2. Security

For many products and industries, EMC performance can mean the difference between life and death. Many medical, military, industrial, aerospace and automotive products (among others) have safety-critical applications.

If the functionality of these products were to fail due to electromagnetic phenomena such as power surges, ESD or radiated electric fields, lives would certainly be at risk. Imagine 300 cell phones all transmitting 7 watts of power to an airplane at 36,000 feet - rigorous EMC testing would be required to ensure that the electrical system could withstand the interference of such an electromagnetic environment and still function properly. Then there are medical devices, such as life-support-related products, where the consequences of abnormal operation due to interference from other electronics can be severe.

3. Product performance (quality)

The functionality and performance of electronic products can be easily affected by externally and internally generated EMC phenomena. For example, if your internal power conditioning is too noisy, it may adversely affect sensitive analog measurements (for sensor products) or degrade the performance of radio transmitters (for wireless products). These are examples of internal EMC problems.

From the outside, application EMC phenomena can negatively impact a product in an almost infinite number of ways, from data corruption to measurement accuracy to RF performance to IC explosions.EMC testing helps to ensure that your equipment continues to operate as intended in typical EMC environments.

4. Keeping test laboratories and government employees busy

A 2013 official report on non-compliance across Europe noted:351 Non-compliance with TP3T technical requirements601 Non-compliance with TP3T documentation.

It is true that EMC testing can be a huge burden for manufacturers large and small, and now that EMC testing in this country is billed by the hour, and in some cases by the project, the high cost of testing and certification, and the technical pressures can be burdensome for some manufacturers, and so their validity is sometimes questionable. However, EMC testing standards in various countries do emerge as a result of real problems (see history below), and business units and company infrastructures are growing to accommodate and enforce these rules and standards.

5. Fines

If you're caught in the market with non-compliant equipment, fines and actions can range from the paltry to the gruesome.

A law firm has published a summary of FCC legal proceedings over the past few years, with interesting results. Most of the fines were related to radio transmitters, not tounintentional launchRelated.

FCC penalties range from a "citation" to $2.2 million.

Enforcement appears to be quite low, as evidenced by a noncompliance rate of about gt;60% in parts of Europe with a sample size of 10,000 products.

The most likely ways that non-compliant equipment will be caught in the marketplace include your competitors notifying the Quality Assurance Bureau, leaked test reports, market surveillance, and finally, customer complaints due to interference with other equipment.

History of EMC electromagnetic compatibility testing

One of the earliest EMC regulations was initially formed in Europe in the early 1900s in response to specific problems arising from the use of electrical equipment. Defective electric lights caused other lights in the neighborhood to "flicker". This was in the era of new power grids in London, England and some other affluent places. To curb this problem, the first EMC legislation may have been enacted, known as the Lighting Clauses Act of 1899!

Germany later beat the UK to the punch with the Imperial German Telegraph Act of 1892, which dealt with the effects of EMC interference on products and devices in the field of telegraph communications. This was due to the discovery that communication cables could have a negative impact on each other.

The FCC has limited transmitter emissions since 1938 and has continued to expand its rules over the ensuing decades in response to the increase in transmitters and electronic equipment. The rules became somewhat haphazard. Unregulated, the FCC standardized emission limits for general application products in 1989.

The EMC Directive was introduced in the European Union in 1992 to standardize requirements across EU member states and to free up mobile and electronic products.

Future Trends:

Standardization of rules

There is a concerted global effort to standardize EMC test requirements, primarily led by the IEC (International Electrotechnical Commission), which generates standards that can be transposed by countries into their own local standards, which theoretically standardizes EMC requirements across all regions that have adopted the IEC standards. For example, most GB standards are derived from IEC standards.

Expanded test requirements

In some countries, such as the US and Canada, only EMI testing is currently required (unless your product falls within the scope of an industry-specific standard requiring EMS testing). In Europe, both EMI and EMS testing (EMC = EMI + EMS) are mandatory. If your products are exported to these countries, they need to be tested and certified according to local regulations.

Over the past few years, countries such as Australia and New Zealand have followed the European model and also require exemption testing. The push from testing laboratories, governments and international standards all indicate that the demand for EMS testing is increasing.

Integration of emc test labs

The FCC's recently announced new rules for EMC test labs mean that only accredited and officially recognized test labs will be accepted for transmitter "certification" testing. Of the 1,000 or so test sites registered with the FCC, about 2/3 are currently not accredited. The additional requirements may favor larger test laboratories, which can absorb the overhead and staffing costs of accreditation, and may force smaller test laboratories out of business.

So the configuration of the corresponding electronic product standard EMC test equipment and test systems for self-test enterprises and testing units are particularly important. Test standards are updated almost every year, and different types of electronic products have different standards, if you do not pay attention to the standard updates, test equipment test capabilities do not meet the latest test standards, but they do not know, until the final national certification to find the problem.

How to test EMC?

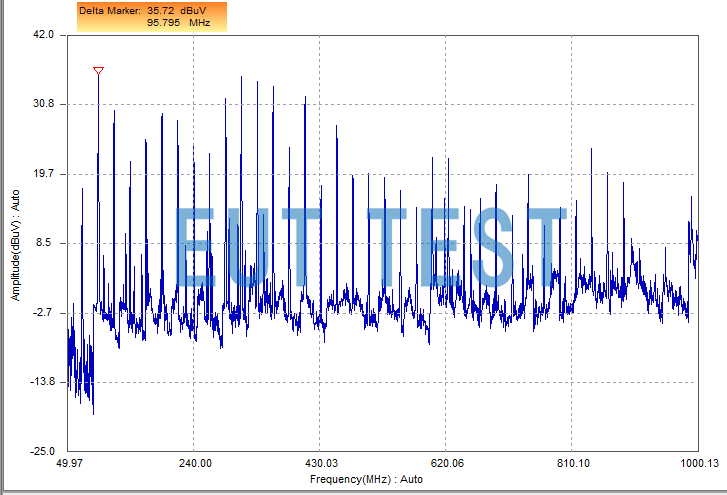

Choose to meet the standard requirements of the EMC test system can be completed on a variety of electronic circuit products EMC testing and certification, such as for small electronic products can be usedTEM-CELL for radiated emission and radiated immunity testingFor large electronics, you can use the darkroom and theEMC antenna for radiated emission and radiated immunity testingThe

Shenzhen EYT Test Technology Co., Ltd. provides test instruments and equipments in line with various EMC test standards; click to learn more about EMC test equipments.Unveiling EMC electromagnetic compatibility test equipment, the guardian of electronic product quality!