Introduction:

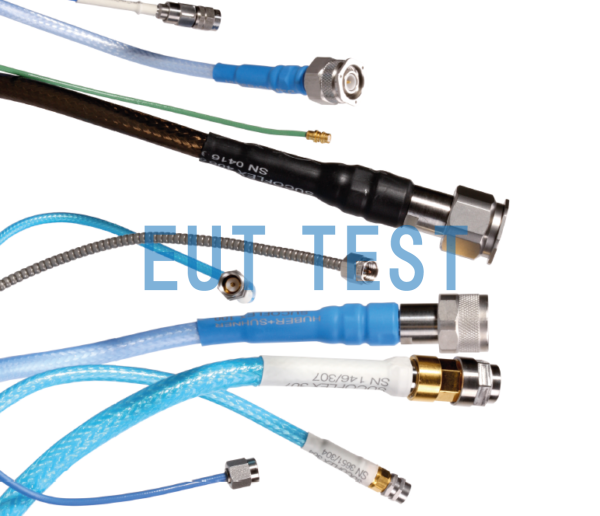

RF cables are available in coaxial, biaxial, triaxial and many more types, EUTTEST agents sell cables with impedances of 50Ω and 75Ω, and test frequencies from DC-110GHz or higher, and for most wireless RF tests and EMC tests only up to 40GHz. the following will detail the different classifications of common RF cables.

The use of RF cables:

- Radio communication systems

- cell phone network

- Domestic Applications, Digital Audio, TV Channel Distribution Networks

- Specialized RF test and measurement systems, laboratories and development units

- Precision communications equipment for the aerospace industry

- Wireline telephone and communications networks

- Military and space applications

- Ship and naval communications systems

- satellite communications

- RF Devices for Healthcare

Components of RF cables:

Components of RF cables

- Center Conductor:This is a solid or stranded wire made of copper or aluminum that is used to carry electrical signals.

- Insulating Layer:Surrounding the center conductor is insulating material that prevents signal leakage and maintains signal integrity.

- Metallic Shield:Metal shields are usually made of braided copper or aluminum foil. Its purpose is to protect internal components from external electromagnetic interference and to help contain RF signals within the cable.

- Outer Insulation (Jacket):This is the outermost layer of the cable and is made of insulating materials such as PVC (polyvinyl chloride) or PE (polyethylene). It provides mechanical protection for the cable against moisture and environmental factors that can affect signal transmission.

1, Classification of RF cables:

1.1, Classification of cables according to their characteristic impedance:

The characteristic impedance of RF cables does not change with length, so you only need to choose one impedance according to the test needs, but note that the attenuation of the cable will increase as the cable gets longer.

- 50Ω cable: used for radio frequency test instrumentation equipment and high frequency test applications. For example, EMC electromagnetic compatibility testing, wireless signal testing.

- 75Ω cable: used for video transmission, digital audio and TV relay signals and other applications.

1.2, Categorized by the flexibility of the cable

- Semi-Rigid RF Coaxial Cable: Rigid Material

- Semi-flexible RF coaxial cable: somewhat softer than semi-rigid

- Flexible RF coaxial cable: most common flexible cable

- Ultra-flexible RF coaxial cable: tolerates multiple 90° rotations of cable/connector

- Miniature RF coaxial cable: small outer diameter, commonly used in laptop computers, cell phones and other internal RF transmission applications.

Miniature RF Coaxial Cable

1.3, Classification by type of shielding layer

Single braided shield:Identified in the cable model number as: S, using metal mesh shielding

Double preparation of the shield:Identified in the cable model number as: D, using metal mesh shielding

double-braided shielding

Corrugated Shield:Use a shield similar to a water ripple to shield the signal.

RF Cable - Ripple Shield

Threaded shield:Use a threaded style shield to shield the signal.

1.4, Classification of external armor for RF cables:

TPU:

RF Cable External Armor - TPU

These cables consist of a steel spring (round wire), a steel braid and a polyurethane (TPU) jacket.

This reinforced version with temperatures up to +85 °C provides excellent protection against compression, stretch, abrasion and other mechanical forces acting on the cable.

Flexible hose:

RF Cable External Armor - Flexible Hose

This type of cable armor consists of a stainless steel flexible hose. It consists of a stainless steel flexible hose. The reinforcement protects the cable from compression, abrasion, mechanical damage, open flames and hot objects such as soldering irons.

The cable limits the continuous temperature to +165 °C and reaches the maximum connector temperature in the vicinity of the connector.

Aramid yarn woven layer:

External Armor for RF Cables - Aramid Yarn Braided Layer

This type of cable armor consists of a braided layer of aramid yarns impregnated with silicon varnish. Reinforcement protects the cable from abrasion and transient high temperatures.

1.5. Classified by shaft:

coaxial cable

Biaxial cable

Triaxial cable

1.6, Classified by cable type:

Below are several common RF cable type classifications, you can click on the relevant title for more information about that cable type.

RG flexible RF cables:

Also known as Radio Guide Cable, it is a coaxial cable that originated for military use during World War II. The name "RG" stands for "Radio Guide", which is part of the U.S. military standard for radio frequency cables. These cables are used to transmit radio frequency signals and come in a variety of types, each with different characteristics suited to a particular application.

The common ones are RG214, RG223 , RG400 , RG58 and so on.

LMR low loss RF cables:

LMR cables are designed to minimize signal attenuation, which means they retain more of their original signal strength over long cable runs than standard coaxial cables.

SUCOFLEX low loss cables:

SUCOFLEX serial RF cables, manufactured by Huber + Suhner in Switzerland, have a maximum test frequency of up to 50 GHz, extremely low return loss, and can be operated in temperatures ranging from -55 degrees Celsius to 125 degrees Celsius.

Common models include: SUCOFLEX 101 , SUCOFLEX 102 , SUCOFLEX 103 , SUCOFLEX 104 , SUCOFLEX 126 , SUCOFLEX 106 , SUCOFLEX 118, SUCOFLEX 229, SUCOFLEX 240, SUCOFLEX 301, and many others. Models. Sometimes we abbreviate all SUCOFLEX to SF, e.g. SUCOFLEX 101 would be called SF101.

Microbend / Microbend L

- Ultra-Flat, High Performance, Microwave Coaxial Cable Assemblies

- Frequency range up to 90 GHz (85 GHz Microbend L)

- Triple shielding for high isolation

- Direct replacement for 0.047-inch semi-rigid cable

- Guaranteed 10 lb (45 N) pull force

- Reduced insertion loss (Microbend L) compared to standard Microbend cables 30%

Mini141

- Flat, high-performance, ultra-low loss microwave cable assemblies

- Frequency range up to 40 GHz

- Triple shielding for high isolation

- No need for expensive right-angle connectors

- Direct replacement for 0.141-inch semi-rigid cable

Minibend CTR

- minibend CTR phase-constant cables have been developed for phase-critical applications where precise electrical length connections are required.

- Excellent phase and insertion loss stability over temperature range

- Absolute phase change < 300 ppm over the -55 to +125 °C temperature range

- Excellent phase stability at 24 GHz (1.0° bend angle relative to bend phase)

- Revolutionary minibend bend-to-end flexibility: minimum bend radius of 5 mm

Summary:

The above is our company organized the basic knowledge and classification of radio frequency cable, we will improve the content of this page when we get more related new knowledge.

Once you have selected the appropriate RF cable type and model, all you need to do is provide the information below to contact us for a quote and lead time information for AOEMC's customized domestic coaxial cable products:

- A, Impedance Requirements (Refer to Section 1.1)

- B, Soft Needs (Refer to Section 1.2)

- C, Shielding Requirements (refer to Section 1.3)

- D, Known Cable Type (refer to Section 1.6)

- E, RF Connectors

- F, Quantity

Tip: RF cables should be purchased and used in conjunction with RF connectors.

Coaxial cable recommendations:

Our company also sells coaxial cables imported from German schwarzbeck company, please press the frequency range you need to test from the following coaxial cables first:

Selecting the right modelAnd thenProvide cable length and connector type to EUTTEST. Get quotes and lead times from our sales staff.;

We only offer new imported coaxial cables, no used goods or defective products.

- AK 9513 3GHz RF coaxial cable

- AK 9515 G 6GHz RF Coaxial Cable

- AK 9515 E 10GHz RF Coaxial Cable

- AK 9515 H 18GHz RF coaxial cable

- AK 9540 B 40GHz RF coaxial cable

- MSS 9630 RF Coaxial Cable with Ferrite Choke

- Domestic 50Ω coaxial cable customization : short lead time, low price

- RF Connector Selection