Qpd Why is partial discharge testing necessary for digital isolators?

- Article Directory: Learn to Test Digital Isolators

Introduction:

Qpd partial discharge test index requirements

In recent years, digital isolation chips are increasingly trusted by engineers in industrial, medical, automotive and other fields. Digital isolation chips are gradually replacing traditional optocoupler devices because of their remarkable features such as small size, high integration, low power consumption and high communication speed. Digital isolation chip is the core device in the system involving high-voltage safety, so it needs to be strictly screened when it leaves the factory.

UL1577 safety standard clearly stipulates that the products must be tested under 60s or 1.2 times of the insulation voltage withstand condition corresponding to the product specification when leaving the factory, and the products can only leave the factory after passing the high voltage test. Taking the product with isolation strength of 3000Vrms as an example, it needs to undergo the high-voltage test of 60s under AC voltage of 3000Vrms and 60Hz frequency or 1s under AC voltage of 3600Vrms and 60Hz frequency at the time of shipment, and can be shipped out of the factory only after passing the test.

The detection method of the high voltage test specified in UL1577 is to detect the leakage current of the insulation layer. If the insulation layer of the digital isolation chip can withstand the test high voltage, then the detected leakage current of the insulation layer will be relatively small, the value is usually uA level, this is because the application of low-frequency AC high voltage, as long as the isolation of the two sides of the existence of a certain amount of parasitic capacitance, there will be the existence of AC leakage current. However, if the insulating layer of the digital isolation chip is not able to withstand the corresponding high voltage, then the insulating layer will produce uncontrollable leakage current because of the high voltage, which finally leads to the damage of the isolation band.

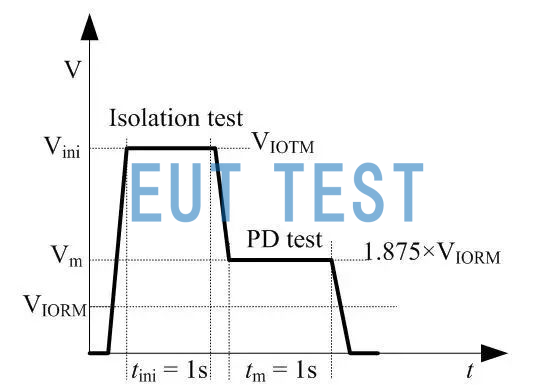

Usually digital isolation chip insulation layer in the production of manufacturing time has a high degree of environmental cleanliness requirements, there can not be bubbles or the existence of voids, so as to ensure good insulation effect and long insulation life. However, in the actual production process, it is difficult to ensure that all chips 100% ensure that the insulation layer has no air bubbles or voids, and the existence of these voids or bubbles will lead to a decline in insulation performance, but these voids or bubbles can not be detected by detecting high-voltage leakage current method. When the high voltage is added at both ends of the insulating medium, because of the existence of these bubbles or voids, a partial discharge (Qpd: Partial Discharge) will be generated, a slight partial discharge on the insulation of the power equipment has a smaller impact, the insulation strength of the slower decline; and a strong partial discharge, it will make the insulation strength decline very quickly. This is an important factor in the damage to the insulation of high-voltage power equipment. Partial discharge will be accompanied by the generation of electric pulse, ultrasonic, electromagnetic radiation, light, chemical reaction, and cause local heating and other phenomena, is the harbinger of the aging of electrical components. Partial discharge detection of the applied voltage is not the insulation withstand voltage value, but added to the insulation layer of the working voltage, because only the working voltage is a long-term role in the insulation layer, and may cause defective products repeatedly charged and discharged, and ultimately lead to premature failure of the insulation layer. Therefore, VDE0884-10 safety regulations stipulate that in addition to the high-voltage leakage current test, partial discharge detection is also required during the factory test. The test voltage for partial discharge detection is 1.875 times the peak operating voltage, the test time is 1s, and the target value of the test result is the size of the leakage charge.

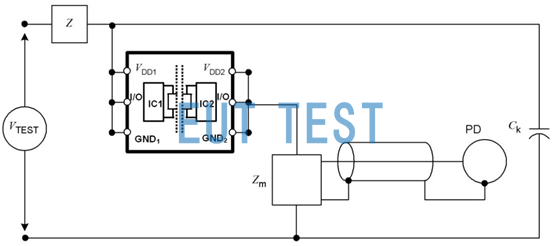

Qpd partial discharge test circuit

Digital Isolation Chip Factory Isolated + Qpd High Voltage Test Waveforms

For the above isolation voltage test and partial discharge test, you can use our agent to sell HT9464M test host for certification test, the maximum test voltage up to AC 10kV rms.

According to customer requirements, our company can customize the configuration of the tester + sorter multi-channel test system, can be automatically completed in the production line of digital isolator Qpd partial discharge multi-channel automated testing.

Multi-Channel Qpd Automation Testing with Sorting Machines

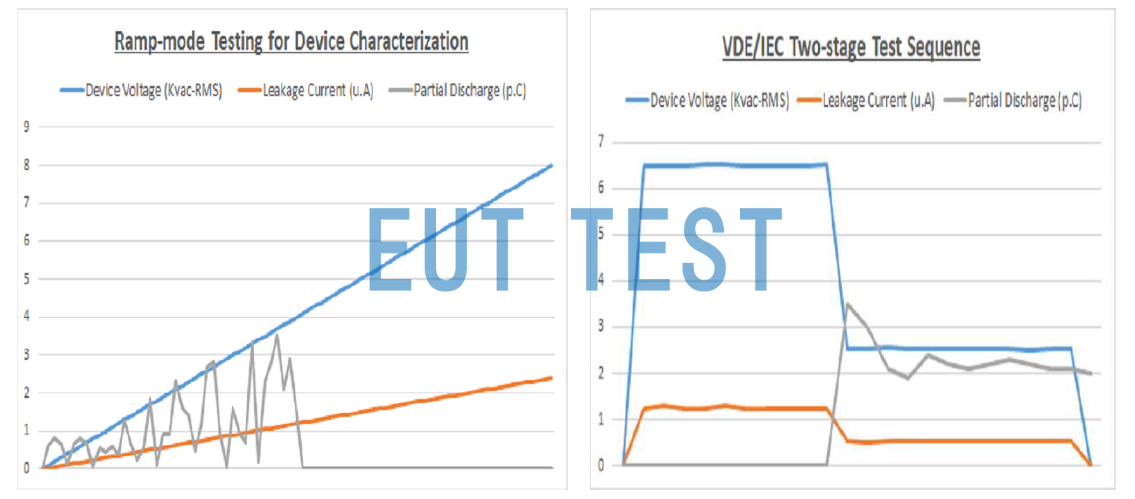

The system comes with a Ramp climb test mode to help digital isolator developers determine the maximum isolation voltage the isolator can withstand and the VDE standard test pattern.

Ramp climb test mode and VDE test mode.

- Created Date: 2024-08-16 10:25:00 ;

- Last modified on 2024-08-16 18:25:00 ;